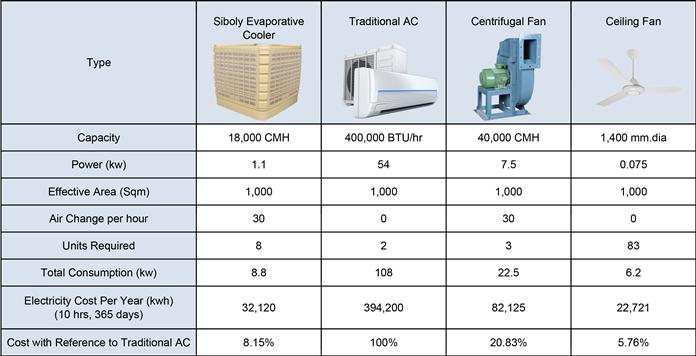

Industrial evaporative coolers consume ~90% less energy than traditional AC units while cooling large spaces—cutting operational costs by thousands annually.

Energy Efficiency Breakdown

1. Power Consumption Comparison

System Type | Industrial Evaporative Cooler (e.g., Siboly 1.5KW) | Traditional AC (Equivalent Coverage) |

Power Usage | 1.5 KW | 15-20 KW |

Cooling Capacity | 20,000 CMH (~200 m²) | 5-7 Tons (60,000 BTU) |

Annual Cost* | $450 | $4,500+ |

Calculations based on 10 hrs/day, $0.15/kWh. Traditional AC requires 3-4x more units for equivalent coverage.

2. Technology Differences

· Industrial Air Cooler: Uses water evaporation (85% efficiency) to cool air naturally.

· Traditional AC: Relies on energy-intensive refrigerant compression cycles.

3. Operational Savings

· Industrial Cooler: $0.22/hour to run

· Traditional AC: $2.25+/hour

Facilities cooling 5,000 m² save ~$50,000/year with evaporative systems.

��� Environmental Impact

Factor | Industrial Cooler | Traditional AC |

CO2 Emissions | 1.2 tons/year | 12+ tons/year |

Refrigerants Used | None (eco-friendly) | HFCs (high GWP) |

Water Usage | 40L/day (recyclable) | None |

GWP = Global Warming Potential. Coolers win on carbon footprint but require water access.

��� Real-World Applications

✅ Best for Industrial Coolers

· Warehouses (e.g., automotive plants)

· Workshops with high ceilings

· Outdoor/ventilated spaces (cafés, markets)

· Dry climates (<60% humidity)

❌ Traditional AC Preferred

· Humid coastal regions

· Sealed server rooms

· Precision temperature labs